Information about the product

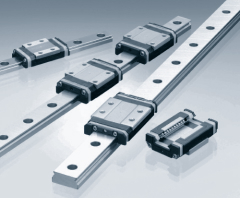

Our range of bearings includes ball bearings, roller bearings, needle roller bearings and plain bearings of all kinds. The following sub-categories are intended to give you a brief insight into our bearing product portfolio.

Of course, we can also procure any special parts that are not listed here. Please get in touch with one of our advisors. We will help you to find the right solution for your problem.

You are also in good hands with us when it comes to accessories for bearings and linear guidance systems.

Cylindrical roller bearing

Cylindrical roller bearing

Brief description:

Cylindrical roller bearings can be separated. Both bearing rings can be fitted in a fixed manner if required. Cylindrical roller bearings withstand high radial loads and are suitable for use with high revolutions. Amongst other issues, damaging edge stresses can be prevented thanks to the modified arrangement of the contact surfaces.

Available designs:

- Two fixed ribs on the outer ring – inner ring without ribs (NU construction)

- No ribs on the outer ring – inner ring with two fixed ribs (N construction)

- Two fixed ribs on the outer ring – one fixed rib on the inner ring (NJ construction)

- Two fixed ribs on the outer ring – one fixed rib on the inner ring + ribbed disk (NUP)

- Two fixed ribs on the outer ring – one fixed rib on the inner ring + angular ring (NJ)

- Various cage designs available

Areas of application:

Self-aligning ball bearings are used in transmissions and large electrical motors for example.

Special bearings

Special bearings

Some special parts from our product range – irrespective of the construction of the bearing – will be described in this category:

- Spindle bearing / high-precision bearing for revolutions of up to 250,000 rpm

- Instruments and miniature bearings

- Thin-section bearings

- Electricity-insulated bearings

- High / low temperature bearings

- Compound bearings (with solid lubricant)

- Separated bearings

- Rotary joints

- Crossed roller bearings

- Special bearings for wind energy systems

- Pot rollers / ball rollers

- Special bearings according to technical drawings

- Special bearings for the food/beverage industry

Separable ball bearings

Separable ball bearings

Brief description:

With regards to their composition, the separable ball bearings correspond to the deep groove ball bearings. However, these bearings only have one collar on the outer ring and, as a result, can be separated. This speciality provides the user with advantages in particular installation cases. Separable bearings always require a second bearing for counter-stay purposes or must be appropriately axially pre-stressed via the shaft.

Available designs:

- Standards and dimensions in accordance with DIN 615

- Metric or imperial

- Sheet-metal cage

Areas of application:

Separable bearings are primarily used in the field of machine tool construction.

Angular contact ball bearing / spindle bearing

Angular contact ball bearing / spindle bearing

Brief description:

Alongside radial forces, single row angled contact ball bearings can also withstand axial forces in one direction. Unlike the separable bearings, the angled contact ball bearings cannot be separated. The loads are transferred from one ring to another at an angle – the pressure angle – measured to the radial plane. Angled contact ball bearings are manufactured with various pressure angles. When the pressure angle increases, the ability of the bearing to withstand axial forces also increases.

With regards to single row angled contact ball bearings, a force occurs in an axial direction – even when dealing with a radial load. This is caused by the pressure angle and must be compensated for by means of an appropriate counter-force. Therefore, a second bearing must be used for counter-stay purposes. The other alternative is to use double row angled contact ball bearings. With regards to composition and function, these correspond to a pair of single row angled contact ball bearings in an O-arrangement.

Available designs:

- Single or double row

- Open or sealed

- Various pressure angles possible

- Various bearing arrangements possible (X/O/Tandem arrangement, etc.)

- Metric or imperial

- Various cage designs available

- Double row, with/without filling groove

- Spindle bearing / high-precision bearing for revolutions of up to 250,000 rpm

- Hybrid bearing (with ceramic ball bearings)

Areas of application:

Angular contact ball bearings are used to support ball screws, drilling machines or in the form of wheel bearings in the automotive industry for example. Grinding spindles are also supported with high precision angular contact ball bearings.

Deep groove ball bearing

Deep groove ball bearing

Brief description:

Deep groove ball bearings are the type of bearing that are most often used. These bearings are particularly inexpensive due to the fact that they are mass-produced.

Single row deep groove ball bearings can withstand radial and axial forces. Due to their low friction torque levels, these bearings are well suited for use when dealing with high revolutions. All deep groove ball bearings can be supplied in an open manner, or sealed with a cover disk (ZZ supplement) or gaskets (2RS / VV supplement). When dealing with the gaskets, a distinction is made between grinding (2RS) and non-grinding (VV). The bearings that are sealed on both sides will be supplied with various types of grease and various degrees of filling in accordance with the respective requirements.

With regards to their composition and function, the double row deep groove ball bearings correspond to a pair of single row deep groove ball bearings. These bearings should not be used if angle errors have to be compensated.

Available designs:

- Open design or sealed (single / double)

- Metric or imperial

- Miniature bearings (from 1 mm inner diameter)

- Metal or plastic cage

- With increased bearing clearance

- Stainless steel material

- Electricity-insulated design

- Special greasing or oiled

- With groove and ring located on the outer ring

- Hybrid bearing (ceramic ball bearings)

- Sound-tested design

Areas of application:

Deep groove ball bearings are used in the most varying of sectors. Amongst other areas, these bearings can be found in the fields of motor and pump construction and conveying engineering as well as in fitness equipment and even in the aviation and space industries. The miniature deep groove ball bearings are used in dental equipment and in the field of model-making for example.

Spherical roller bearing

Spherical roller bearing

Brief description:

Spherical roller bearings have two roller rows that unroll in a joint hollow spherical outer ring track. Spherical roller bearings are angle-adjustable and are therefore not sensitive to misalignments. Alongside high levels of radial forces, these bearings can also withstand axial forces in both directions. These bearings are supplied with cylindrical and spherical holes. In the event that the hole is spherical, the bearing is attached with a tension / withdrawal sleeve or the bearing will be assembled directly onto the spherical shaft.

Available versions:

- High temperature design

- Spherical or cylindrical hole

- Available in various cage designs

- Sealing possible with Nilos rings

- Can be supplied with lubrication groove or lubrication hole

- Can be supplied in metric or imperial

Areas of application:

Amongst other areas, the spherical roller bearings are used in two-part cases, to support vibrating screens in the field of mining as well as in rolling mills. These bearings can also be found in the wind power, transmission manufacture sectors, etc.

Self-aligning ball bearing

Self-aligning ball bearing

Brief description:

Self-aligning ball bearings are double-row bearings with a hollow spherical outer ring track. As a result, the bearings are angle-adjustable and, as a result, are suitable for compensating for angle errors.

Self-aligning ball bearings will be supplied with cylindrical and tapered hole. The bearings with tapered holes will be attached to the shaft with a tension sleeve.

Available designs:

- Open or sealed

- Can be supplied with widened inner ring

- Metric or imperial

- Conical / cylindrical hole

- Can be supplied with tension or clamping sleeves

- Can be supplied in various cage designs

Areas of application:

Self-aligning ball bearings are primarily used in two-part casing bearings.

Needle bearing

Needle bearing

Brief description:

Needle bearings are manufactured in the most varying of versions and constructions. For this reason, it is extremely difficult to make a general statement about these units. Needle bearings are always used where high radial forces exist and there is little room to install the bearing.

Available designs:

- Needle roller and cage assemblies (also for connecting rod bearings)

- Needle sleeves and bushes with and without sealing

- Needle bearing with / without ribs, with/without inner ring, including sealing

- Adjustment needle bearings

- Combined needle bearings

- Inner rings

- Support rollers and cam rollers (also with eccentric)

- Needle axial cylindrical roller bearing

Areas of application:

Needle bearings are often used when fitting motors for connecting rod bearings as well as in the fields of transmission manufacture, model-making and general machine construction.

Axial deep groove ball bearing

Axial deep groove ball bearing

Brief description:

Single and double direction axial deep groove ball bearings are able to withstand high axial loads but may not be placed under radial load. These bearings are manufactured with flat or spherical housing washers complete with support washers.

Available designs:

- Single and double direction

- Various cage designs are available

- Various tolerance classes are available

Areas of application:

Axial deep groove ball bearings are used in the fields of pump and turbine construction, bench drilling machines as well as machine tools for example.

Tapered roller bearing

Tapered roller bearing

Brief description:

Alongside radial forces, tapered roller bearings are also able to withstand axial forces in one direction. As is the case with the angled ball bearings, the loads are transferred from one ring to another at an angle – the pressure angle – measured to the radial plane. Even when dealing with pure radial loads, a force working in one axial direction will occur due to the pressure angle. These forces must be withstood either by pre-stressing or by using a counter-bearing. Tapered roller bearings can be dismantled. Therefore, the inner ring complete with roller set and the outer ring are to be installed separately.

Available designs:

- Standard / reinforced design

- Pressure angle in accordance with ISO

- Various casing designs available

- Can be supplied individually or in pairs

- Can be supplied in metric or imperial

Areas of application:

Amongst other areas, tapered roller bearings are used in construction machines, HGVs and heavy goods trailers in the form of wheel bearings or on motorbikes in the form of steering head bearings.

Axial spherical roller bearing

Axial spherical roller bearing

Brief description:

Axial spherical roller bearings are able to withstand extremely high axial loads that are transferred at an angle to the bearing axle. These bearings can also be placed under radial loads. However, the radial load may not exceed 55% of the axial force.

Available versions:

- Standard / increased load bearing capacity

Areas of application:

The areas of application of the axial spherical roller bearing are similar to those of the axial deep groove ball bearings and of the spherical roller bearing.

Plain bearing

Plain bearing

Brief description:

Plain bearings are coated bushes. Low frictional torque levels are achieved thanks to the coating. Plain bearings are designed for longitudinal as well as rotary movements. Furthermore, these bearings are characterised by their low weight and compact installation dimensions.

Available designs:

- Plain bearing with / without collar

- Plain bearing manufactured from metal, multi-layer compounds and plastic

- Maintenance-free

- Chemically resistant

- Metric and imperial

- Suitable for dry running

Areas of application:

In areas with high dirt levels or underwater for example. These bearings are also used printers and copiers in order to support the paper-feeding device.

Spherical plain bearings / rod ends

Spherical plain bearings / rod ends

Brief description:

Spherical plain bearings are supplied with or without shanks. These products are characterised by the fact that they can be installed with any tilting angle that is desired. Spherical plain bearings withstand radial forces. They transfer forces and movements with low torque levels and, as a result, keep flexural stress away from the construction elements.

Available designs:

- Available designs

- Rod ends – requiring maintenance or maintenance-free

- Hydraulic rod ends

- Adjustment needle bearings

- Maintenance-free rod ends with integrated rolling bearing

- Metric or imperial

- Special rod ends according to technical drawings

- Angled spherical plain bearings

- Axial spherical plain bearings

Areas of application:

Rod ends are often used in special machines in the automotive industry as well in the field of model making.

Housing bearing

Housing bearing

Brief description:

Housing bearings consist of double-sided sealed ball bearings and various types of cases. The angles of the bearings can be adjusted by means of the crowned outer ring. The fixing of the inner ring onto the shafts can take place by means of headless screw, tension sleeves or eccentric clamping rings.

When dealing with heavy loads, it is usually the case that two-part cases with integrated spherical ball bearings or spherical roller bearings are used.

Available designs:

- Various sealing possibilities

- Metric or imperial

- High-temperature design

- Stainless steel bearing and plastic casing for the foodstuff sector

- Various bearing constructions depending upon the application

- Vertical bearing, flange bearing or hanging bearing

- Various fixing possibilities

- Can be supplied with / without sealing caps

- With / without lubrication groove

- Casing and bearing insert can be ordered individually

Areas of application:

Case bearings are often used in the agricultural sector, in conveying systems, construction machines, go-karts and in apparatus engineering.

Cylindrical roller bearing

Cylindrical roller bearing

Brief description:

Cylindrical roller bearings can be separated. Both bearing rings can be fitted in a fixed manner if required. Cylindrical roller bearings withstand high radial loads and are suitable for use with high revolutions. Amongst other issues, damaging edge stresses can be prevented thanks to the modified arrangement of the contact surfaces.

Available designs:

- Two fixed ribs on the outer ring – inner ring without ribs (NU construction)

- No ribs on the outer ring – inner ring with two fixed ribs (N construction)

- Two fixed ribs on the outer ring – one fixed rib on the inner ring (NJ construction)

- Two fixed ribs on the outer ring – one fixed rib on the inner ring + ribbed disk (NUP)

- Two fixed ribs on the outer ring – one fixed rib on the inner ring + angular ring (NJ)

- Various cage designs available

Areas of application:

Self-aligning ball bearings are used in transmissions and large electrical motors for example.

Special bearings

Special bearings

Some special parts from our product range – irrespective of the construction of the bearing – will be described in this category:

- Spindle bearing / high-precision bearing for revolutions of up to 250,000 rpm

- Instruments and miniature bearings

- Thin-section bearings

- Electricity-insulated bearings

- High / low temperature bearings

- Compound bearings (with solid lubricant)

- Separated bearings

- Rotary joints

- Crossed roller bearings

- Special bearings for wind energy systems

- Pot rollers / ball rollers

- Special bearings according to technical drawings

- Special bearings for the food/beverage industry

Separable ball bearings

Separable ball bearings

Brief description:

With regards to their composition, the separable ball bearings correspond to the deep groove ball bearings. However, these bearings only have one collar on the outer ring and, as a result, can be separated. This speciality provides the user with advantages in particular installation cases. Separable bearings always require a second bearing for counter-stay purposes or must be appropriately axially pre-stressed via the shaft.

Available designs:

- Standards and dimensions in accordance with DIN 615

- Metric or imperial

- Sheet-metal cage

Areas of application:

Separable bearings are primarily used in the field of machine tool construction.

Angular contact ball bearing / spindle bearing

Angular contact ball bearing / spindle bearing

Brief description:

Alongside radial forces, single row angled contact ball bearings can also withstand axial forces in one direction. Unlike the separable bearings, the angled contact ball bearings cannot be separated. The loads are transferred from one ring to another at an angle – the pressure angle – measured to the radial plane. Angled contact ball bearings are manufactured with various pressure angles. When the pressure angle increases, the ability of the bearing to withstand axial forces also increases.

With regards to single row angled contact ball bearings, a force occurs in an axial direction – even when dealing with a radial load. This is caused by the pressure angle and must be compensated for by means of an appropriate counter-force. Therefore, a second bearing must be used for counter-stay purposes. The other alternative is to use double row angled contact ball bearings. With regards to composition and function, these correspond to a pair of single row angled contact ball bearings in an O-arrangement.

Available designs:

- Single or double row

- Open or sealed

- Various pressure angles possible

- Various bearing arrangements possible (X/O/Tandem arrangement, etc.)

- Metric or imperial

- Various cage designs available

- Double row, with/without filling groove

- Spindle bearing / high-precision bearing for revolutions of up to 250,000 rpm

- Hybrid bearing (with ceramic ball bearings)

Areas of application:

Angular contact ball bearings are used to support ball screws, drilling machines or in the form of wheel bearings in the automotive industry for example. Grinding spindles are also supported with high precision angular contact ball bearings.

Deep groove ball bearing

Deep groove ball bearing

Brief description:

Deep groove ball bearings are the type of bearing that are most often used. These bearings are particularly inexpensive due to the fact that they are mass-produced.

Single row deep groove ball bearings can withstand radial and axial forces. Due to their low friction torque levels, these bearings are well suited for use when dealing with high revolutions. All deep groove ball bearings can be supplied in an open manner, or sealed with a cover disk (ZZ supplement) or gaskets (2RS / VV supplement). When dealing with the gaskets, a distinction is made between grinding (2RS) and non-grinding (VV). The bearings that are sealed on both sides will be supplied with various types of grease and various degrees of filling in accordance with the respective requirements.

With regards to their composition and function, the double row deep groove ball bearings correspond to a pair of single row deep groove ball bearings. These bearings should not be used if angle errors have to be compensated.

Available designs:

- Open design or sealed (single / double)

- Metric or imperial

- Miniature bearings (from 1 mm inner diameter)

- Metal or plastic cage

- With increased bearing clearance

- Stainless steel material

- Electricity-insulated design

- Special greasing or oiled

- With groove and ring located on the outer ring

- Hybrid bearing (ceramic ball bearings)

- Sound-tested design

Areas of application:

Deep groove ball bearings are used in the most varying of sectors. Amongst other areas, these bearings can be found in the fields of motor and pump construction and conveying engineering as well as in fitness equipment and even in the aviation and space industries. The miniature deep groove ball bearings are used in dental equipment and in the field of model-making for example.

Spherical roller bearing

Spherical roller bearing

Brief description:

Spherical roller bearings have two roller rows that unroll in a joint hollow spherical outer ring track. Spherical roller bearings are angle-adjustable and are therefore not sensitive to misalignments. Alongside high levels of radial forces, these bearings can also withstand axial forces in both directions. These bearings are supplied with cylindrical and spherical holes. In the event that the hole is spherical, the bearing is attached with a tension / withdrawal sleeve or the bearing will be assembled directly onto the spherical shaft.

Available versions:

- High temperature design

- Spherical or cylindrical hole

- Available in various cage designs

- Sealing possible with Nilos rings

- Can be supplied with lubrication groove or lubrication hole

- Can be supplied in metric or imperial

Areas of application:

Amongst other areas, the spherical roller bearings are used in two-part cases, to support vibrating screens in the field of mining as well as in rolling mills. These bearings can also be found in the wind power, transmission manufacture sectors, etc.

Self-aligning ball bearing

Self-aligning ball bearing

Brief description:

Self-aligning ball bearings are double-row bearings with a hollow spherical outer ring track. As a result, the bearings are angle-adjustable and, as a result, are suitable for compensating for angle errors.

Self-aligning ball bearings will be supplied with cylindrical and tapered hole. The bearings with tapered holes will be attached to the shaft with a tension sleeve.

Available designs:

- Open or sealed

- Can be supplied with widened inner ring

- Metric or imperial

- Conical / cylindrical hole

- Can be supplied with tension or clamping sleeves

- Can be supplied in various cage designs

Areas of application:

Self-aligning ball bearings are primarily used in two-part casing bearings.

Needle bearing

Needle bearing

Brief description:

Needle bearings are manufactured in the most varying of versions and constructions. For this reason, it is extremely difficult to make a general statement about these units. Needle bearings are always used where high radial forces exist and there is little room to install the bearing.

Available designs:

- Needle roller and cage assemblies (also for connecting rod bearings)

- Needle sleeves and bushes with and without sealing

- Needle bearing with / without ribs, with/without inner ring, including sealing

- Adjustment needle bearings

- Combined needle bearings

- Inner rings

- Support rollers and cam rollers (also with eccentric)

- Needle axial cylindrical roller bearing

Areas of application:

Needle bearings are often used when fitting motors for connecting rod bearings as well as in the fields of transmission manufacture, model-making and general machine construction.

Axial deep groove ball bearing

Axial deep groove ball bearing

Brief description:

Single and double direction axial deep groove ball bearings are able to withstand high axial loads but may not be placed under radial load. These bearings are manufactured with flat or spherical housing washers complete with support washers.

Available designs:

- Single and double direction

- Various cage designs are available

- Various tolerance classes are available

Areas of application:

Axial deep groove ball bearings are used in the fields of pump and turbine construction, bench drilling machines as well as machine tools for example.

Tapered roller bearing

Tapered roller bearing

Brief description:

Alongside radial forces, tapered roller bearings are also able to withstand axial forces in one direction. As is the case with the angled ball bearings, the loads are transferred from one ring to another at an angle – the pressure angle – measured to the radial plane. Even when dealing with pure radial loads, a force working in one axial direction will occur due to the pressure angle. These forces must be withstood either by pre-stressing or by using a counter-bearing. Tapered roller bearings can be dismantled. Therefore, the inner ring complete with roller set and the outer ring are to be installed separately.

Available designs:

- Standard / reinforced design

- Pressure angle in accordance with ISO

- Various casing designs available

- Can be supplied individually or in pairs

- Can be supplied in metric or imperial

Areas of application:

Amongst other areas, tapered roller bearings are used in construction machines, HGVs and heavy goods trailers in the form of wheel bearings or on motorbikes in the form of steering head bearings.

Axial spherical roller bearing

Axial spherical roller bearing

Brief description:

Axial spherical roller bearings are able to withstand extremely high axial loads that are transferred at an angle to the bearing axle. These bearings can also be placed under radial loads. However, the radial load may not exceed 55% of the axial force.

Available versions:

- Standard / increased load bearing capacity

Areas of application:

The areas of application of the axial spherical roller bearing are similar to those of the axial deep groove ball bearings and of the spherical roller bearing.

Plain bearing

Plain bearing

Brief description:

Plain bearings are coated bushes. Low frictional torque levels are achieved thanks to the coating. Plain bearings are designed for longitudinal as well as rotary movements. Furthermore, these bearings are characterised by their low weight and compact installation dimensions.

Available designs:

- Plain bearing with / without collar

- Plain bearing manufactured from metal, multi-layer compounds and plastic

- Maintenance-free

- Chemically resistant

- Metric and imperial

- Suitable for dry running

Areas of application:

In areas with high dirt levels or underwater for example. These bearings are also used printers and copiers in order to support the paper-feeding device.

Spherical plain bearings / rod ends

Spherical plain bearings / rod ends

Brief description:

Spherical plain bearings are supplied with or without shanks. These products are characterised by the fact that they can be installed with any tilting angle that is desired. Spherical plain bearings withstand radial forces. They transfer forces and movements with low torque levels and, as a result, keep flexural stress away from the construction elements.

Available designs:

- Available designs

- Rod ends – requiring maintenance or maintenance-free

- Hydraulic rod ends

- Adjustment needle bearings

- Maintenance-free rod ends with integrated rolling bearing

- Metric or imperial

- Special rod ends according to technical drawings

- Angled spherical plain bearings

- Axial spherical plain bearings

Areas of application:

Rod ends are often used in special machines in the automotive industry as well in the field of model making.

Housing bearing

Housing bearing

Brief description:

Housing bearings consist of double-sided sealed ball bearings and various types of cases. The angles of the bearings can be adjusted by means of the crowned outer ring. The fixing of the inner ring onto the shafts can take place by means of headless screw, tension sleeves or eccentric clamping rings.

When dealing with heavy loads, it is usually the case that two-part cases with integrated spherical ball bearings or spherical roller bearings are used.

Available designs:

- Various sealing possibilities

- Metric or imperial

- High-temperature design

- Stainless steel bearing and plastic casing for the foodstuff sector

- Various bearing constructions depending upon the application

- Vertical bearing, flange bearing or hanging bearing

- Various fixing possibilities

- Can be supplied with / without sealing caps

- With / without lubrication groove

- Casing and bearing insert can be ordered individually

Areas of application:

Case bearings are often used in the agricultural sector, in conveying systems, construction machines, go-karts and in apparatus engineering.

We are here for you!

Do you have questions about a product from the areas of bearings, linear technology, spindle bearings or seals? Do you need support with the planning of your project or would you like to make an enquiry about stock? The right contact person is ready for you. Feel free to use our chat function!

Our brands

Whether deep groove ball bearings, spindle bearings, miniature bearings, ball screw drives or linear guides - in cooperation with our first-class partners such as GMN, NSK, GRW and HIWIN, we offer you high-quality products that fulfil even the highest requirements.

Our priority is high availability! Our central warehouse in Nuremberg currently stocks rolling bearing and drive technology products worth around 6.9 million euros.